Carrier Furnace Repair – Control Board Replacement & Overflow Protection Installation

When a furnace suddenly stops heating, the cause is often a hidden issue inside the system. Many of these problems go unnoticed until the furnace finally shuts down. Today’s service call was about a Carrier furnace that wasn’t heating. The inspection showed why regular maintenance and safety parts are important, especially in winter.

Understanding the components of a furnace can aid homeowners in recognizing early signs of trouble. For example, the igniter makes a flame for heating. If it fails, the whole system won’t work. Regular checks on the igniter and other components can help prevent costly repairs down the line.

The homeowner reported that their furnace was completely unresponsive. The system we serviced was a Carrier 58stx110, a high-efficiency model that requires correct drainage to operate safely. During our diagnostic, we checked the ignition sequence, airflow, sensors, electrical components, and the drain system. Right away, we noticed moisture inside the furnace cabinet, which is a strong indicator of a drainage failure.

During our inspection, we also noted the age of the furnace, which can impact its performance. Older models may lack the efficiency of newer units, often leading to higher energy bills and more frequent repairs. Homeowners should consider the long-term costs of keeping an outdated system versus upgrading to a more efficient model.

What We Found

Carrier Furnace Repair: Common Issues and Solutions

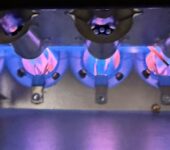

High-efficiency furnaces create condensation during normal operation. This water should drain through a primary drain line. In well-installed systems, there is a secondary drain line. This line acts as an overflow safety switch. It stops the furnace if the main line gets blocked.

To illustrate the importance of the secondary drain line, consider a scenario where a homeowner neglects regular maintenance. A clogged primary drain can cause water damage. This can harm the furnace and create problems in the home’s structure. This highlights the importance of preventive measures in maintaining furnace health.

In this system, only the primary drain line was present—and it was completely clogged. With nowhere for the water to drain, it backed up into the furnace cabinet. The overflow caused water to run onto sensitive components, including the main furnace control board, which was badly damaged. The control board is responsible for managing ignition, blowers, sensors, and communication between all internal parts. Once water reaches it, the furnace cannot run safely or reliably.

Furthermore, understanding the role of the control board can empower homeowners. This component acts as the brain of the furnace, managing various functions. Knowledge about its importance can encourage timely repairs and replacements, ensuring the system functions effectively when needed most.

This was the direct reason the furnace stopped heating.

Repairs Performed

To restore operation and protect the equipment from future damage, we completed two essential repairs.

1. Control Board Replacement

Replacing the control board also involves a thorough testing process. For instance, we verify the communication between the thermostat and the control board to ensure accurate temperature readings. This step is critical in optimizing energy efficiency and maintaining comfort.

We replaced the damaged control board with a new OEM component designed for the Carrier 58stx110. After installation, we tested the whole heating cycle. This included the inducer, ignition, flame sensing, blower performance, and all safety switches. The furnace started up correctly and ran through a full heating cycle with stable performance.

2. Overflow Safety Switch Installation

Because the original installation lacked secondary protection, we added an overflow safety switch. This device automatically shuts down the system if water begins to rise due to a clogged drain. It prevents future flooding and protects the electronics from moisture exposure. Installing this type of safety switch is a simple, affordable upgrade that can save homeowners from costly repairs.

The addition of an overflow safety switch serves as a crucial safeguard. For instance, if a homeowner experiences a heavy rain or snowmelt, the chances of drain clogs increase. This switch will activate, preventing any water damage and ensuring that the furnace operates without interruption.

Why Drain Protection Matters

Condensation management is one of the most overlooked aspects of high-efficiency furnace maintenance. A small blockage in the drain line can cause water leaks, corrosion, electrical damage, and system failure. When safety parts like secondary drain lines, overflow switches, or float switches are missing, the risk of damage goes up a lot.

Homeowners should also be aware of other maintenance tasks, such as changing air filters regularly. Clogged filters can reduce air quality and efficiency, leading to higher energy use. By keeping filters clean, homeowners can enhance their furnace’s performance and overall longevity.

Regular inspections and simple upgrades can protect your furnace and extend its lifespan. Preventive maintenance also helps catch small issues before they turn into major repairs.

For additional information on heating system services, you can visit our helpful pages:

There are also numerous resources available for homeowners looking to educate themselves further about their heating systems. Online forums, local workshops, and educational websites provide valuable insights into maintaining a furnace and understanding common issues.

Final Results

Ultimately, achieving optimal performance from a heating system hinges on proper care and maintenance. This includes regular professional inspections and being vigilant about any unusual noises or changes in operation. Homeowners who invest time in understanding their systems will likely enjoy greater comfort and fewer unexpected breakdowns.

After we installed the new control board and overflow switch, we checked the system. It was running smoothly and showed better efficiency. The homeowner expressed relief in knowing that their furnace is now equipped to handle potential drainage issues. This case shows how important preventative measures are. They can change a costly repair into an easy upgrade.

Contact Information

For those considering a new furnace, it is crucial to evaluate energy efficiency ratings. High-efficiency models may cost more at first. However, they can save you a lot on utility bills over time. This makes them a good investment in the long run.

GoTech Air Conditioning & Heating

Phone: (949) 228-6242

Email: gotech.hvac@gmail.com

Website: https://www.gotech-hvac.com

CA License #1120123

Additionally, staying informed about the latest technologies in heating systems can provide homeowners with better options. Features like smart thermostats can enhance energy efficiency, providing homeowners with control over heating schedules and preferences, thus optimizing energy consumption.

In conclusion, proactive maintenance and understanding your furnace’s components are key to ensuring reliable operation. Regular inspections and timely repairs can help your furnace last longer. Upgrades, like adding an overflow safety switch, also improve performance during the heating season. For expert assistance, remember to reach out to professionals who specialize in Carrier furnace repair.